Having crossed the halfway point of the 2000s, some prestigious semiconductor manufacturers declared that in the following years they would start selling high-power, high-efficiency light emitting diodes (LEDs) with a long lifespan.

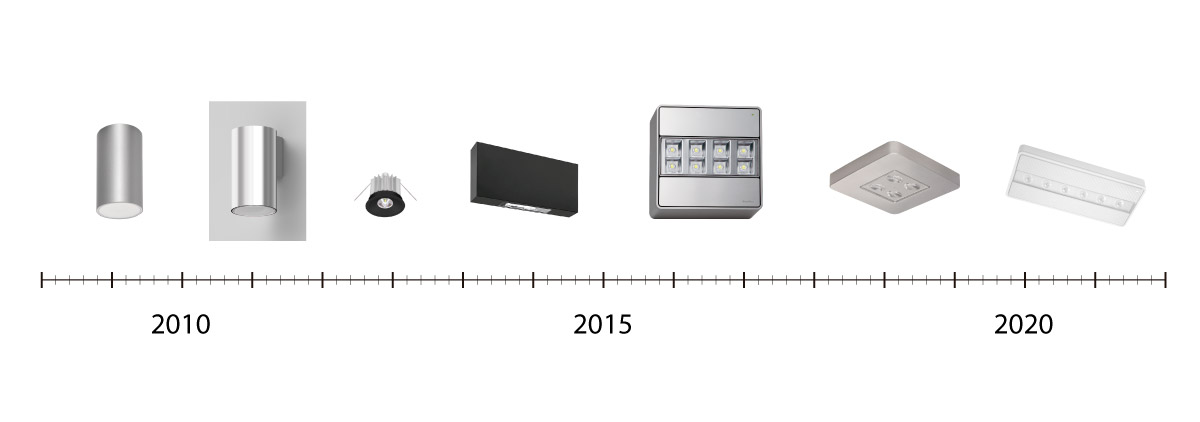

This technological leap marked the beginning of a frantic activity in Daisalux’s R&D department, which allowed for changes in the shapes and proportions of new luminaire developments, due to the drastic reduction in the size of the light source (from a fluorescent tube to one or several LEDs).

It was possible to design smaller emergency luminaires with different proportions, more discreet and facilitating integration. On the other hand, it was possible to reduce luminaire consumption and save on maintenance costs.

However, despite being a more efficient and durable lamp, it did not have photometry suitable for the requirements demanded in emergency lighting. With the opening of this field to investigate with a great margin for improvement, Daisalux created a Department of Applied Optics, which in the last 15 years has become one of the cornerstone pieces upon which the development of our products pivots.

Benefits of Microstructure

The optical assembly plays a key role in an emergency luminaire. In this article, we will take a look at how Daisalux has designed different models of optical assemblies over time, each with its own unique properties and advantages. An engineering feat that fits in the palm of your hand.

But for now, let’s focus on the latest creation from Daisalux’s R&D department, the Naos Series, an emergency luminaire designed to provide functionality in a variety of architectural environments.

This luminaire includes a new optic that functions through a Microstructured Surface. This is an optic that is a few microns thick and is etched into the diffuser using a mathematical pattern. Light is refracted by this relief and reaches the desired lighting objectives, just as it would with a conventional lens and reflector.

This technology, also known as Microstructure (MCRled), has revolutionized the work methodology of Daisalux’s Optics Department.

Firstly, thanks to Microstructures, the number of elements used in the optical assembly is reduced, as is its complexity and size. By dispensing with the reflector and diffuser, material costs are reduced, as is the complexity of the optical assembly, saving time in development and testing.

Another fundamental aspect to consider of Microstructures are their refractive properties, which result in high-quality light projection. Its technical characteristics are considered to be comparable to those of traditional optics. The result is a photometric curve and uniformity similar to that obtained with a conventional lens and reflector, but in a much smaller space.

Looking at the technical side, it seems like there are only advantages. But what about the aesthetic part?

It turns out that a Microstructure (MCRled) can be formed on surfaces as thin as 2 millimeters. These are very small dimensions, especially when compared to the size of other lenses. This characteristic determines the final design of the device. As a result, more compact and discreet luminaires can be produced that blend in better with the environment.

Process of development and industrialization of Microstructures

As a summary, we can take a brief look at the stages involved in the development of this new type of optics.

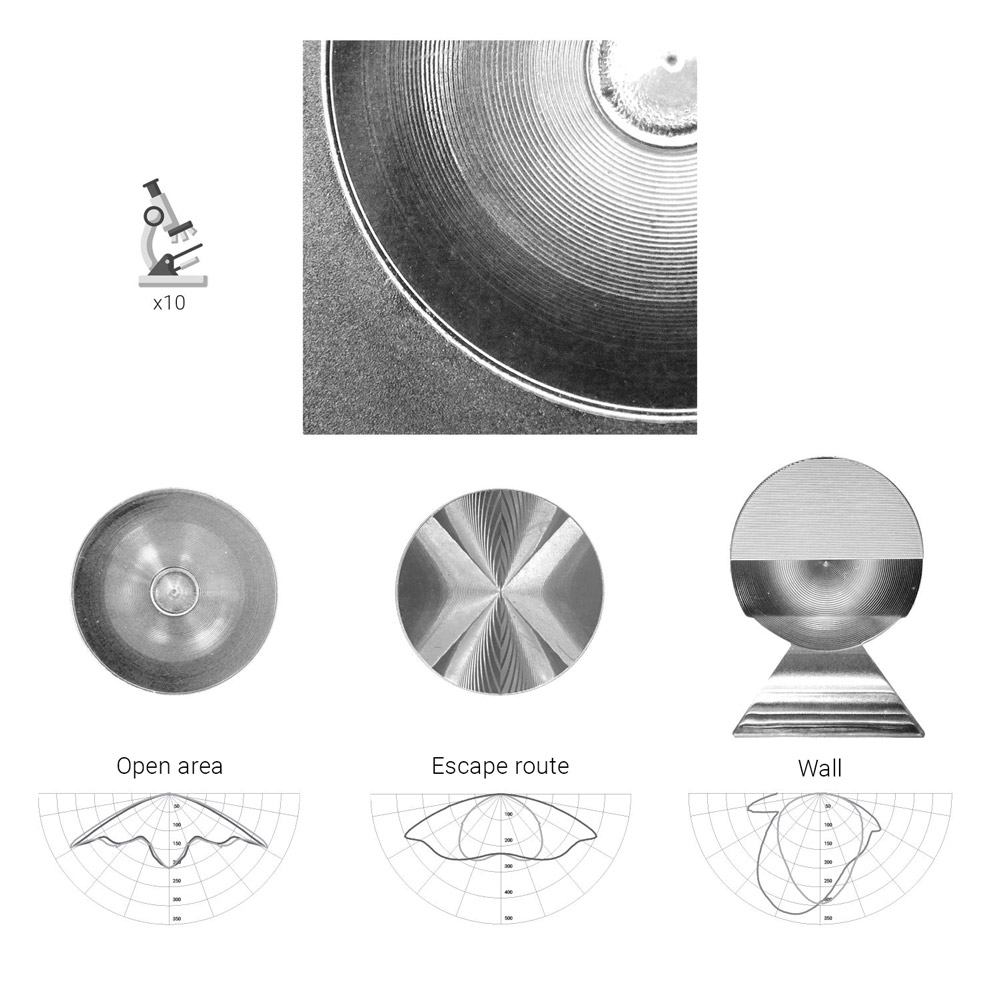

As with any optic, the initial step would be to define the objectives of the Microstructure (MCRled) and its photometric curve. In this first phase of development, 3 Microstructures have been designed for the Naos Series. One optic is for panic lighting that illuminates open areas from the ceiling, another to illuminate evacuation routes, corridors, and narrow areas from the ceiling, and another to illuminate from the wall as a floor washer for both open areas and evacuation routes.

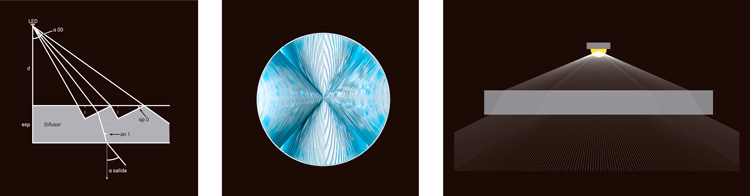

Next, with the help of computer simulations, the mathematical pattern that the optics must follow to achieve its objectives according to the luminous flux of the LED is calculated, a 3D simulation is performed, and the validity of the study is checked. From this model, the experimental prototype manufacturing begins.

In the following image, the mathematical calculation, the 3D model, and the simulation with rays of light can be observed.

The manufacturing process is not an easy task either, as the microscopic dimensions of each groove in the relief make it difficult to reproduce the model correctly. After many manufacturing trials, and once a valid methodology is achieved, an industrial production plan is initiated to proceed with the manufacture of the Microstructure (MCRled) on a large scale.

In the following graph, the imbalance that occurs between simulation, mold, and the final result during the forming of the texture can be checked. Of course, the manufacturing process is not considered valid until a reduced margin of error is achieved. For the development of the Naos Series optics, up to fourteen modifications of the model have been made to achieve the definitive one.

Evolution of Optics at Daisalux

If we look back, we can see that the design and use of optics has played a fundamental role in the development of our products over the last decade. It can be said that this adventure began in 2010 with the Lens Series, the first emergency luminaire that incorporated a LED and a lens in its optical assembly from its launch. Since then, Daisalux’s Optics Department has not stopped in its efforts to develop more effective, efficient, and compact optics. The latest step in this evolution has been the development of Microstructured Surfaces, but let’s go back to the origin to understand the fundamentals of this evolution.

At first, the Lens Series incorporated 3 different optics, each for a specific height range. Later, a fourth lens was developed to place this luminaire on the wall and take advantage of all its luminous flux.

The subsequent launch was the Izar Series, which was the first luminaire to incorporate different lenses depending on the surface to be illuminated. One was called Antipanic and the other had a more elongated curve, designed to cover evacuation routes.

Next came the development of the Block Series, a luminaire for surface wall placement. The photometric curve of this device is optimized to project light from the vertical plane thanks to an optical assembly consisting mainly of a LED along with a reflector.

The Atria Series is made up of a set of projectors designed for large heights and surfaces that have a combination of lenses and an aluminum reflector for optimal light distribution both for ceiling and wall lighting. In this case, the reflector manages to orient the rays of light at angles where the lens is less effective.

Just before the Naos Series, the Ziner Series arrived. In this case, flat lenses were developed on the outer part combined with a reflector of the same color as the product, allowing for better integration into the architecture.

In the development of the Naos Series, Microstructured Surfaces have been used for the first time, providing technical performance in line with the evolution of the previous optics developed by Daisalux, but with the advantage of their simplicity as they are composed of a single flat optical element.

For Daisalux, designing and manufacturing an optical element of these characteristics and size has been quite a challenge.

As an example of the complexity faced by Daisalux’s R&D team, we can take the Microstructure used for evacuation routes of the Naos Series. Like grooves in the relief of the Microstructure, in its 17 mm diameter and 2 mm thickness, it contains more than 150 small micro-optics. All together, they form the Microstructured Surface.

Each of these grooves must be molded with an exact angle and length to cause the desired refraction of each ray of light and obtain the photometric curve necessary to meet the lighting requirements of the emergency lighting project.

This advance in the optical assembly, which previously consisted of several elements, is now reduced to one. Not to mention the reduction in volume, which is obvious.

From now on, improving its performance and developing new photometries will be an important part of the work of our Applied Optics Department.

Leave A Comment